Advantages of Quenching Oil Filtration

Enhanced Heat Treatment: Maintains consistent oil cleanliness to achieve precise and uniform heat treatment results, improving component hardness and durability.

Extended Oil Life: Removal of contaminants prolongs quenching oil life, reducing replacement frequency and operational costs.

Improved Equipment Reliability: Minimizes wear and tear on equipment by preventing contaminants from causing abrasion or clogging, ensuring reliable operation.

Cost Savings: Reduces downtime and maintenance costs associated with equipment failures or premature oil degradation, optimizing overall operational efficiency.

Environmental Benefits: Minimizes waste and environmental impact by promoting the reuse of quenching oils through effective purification.

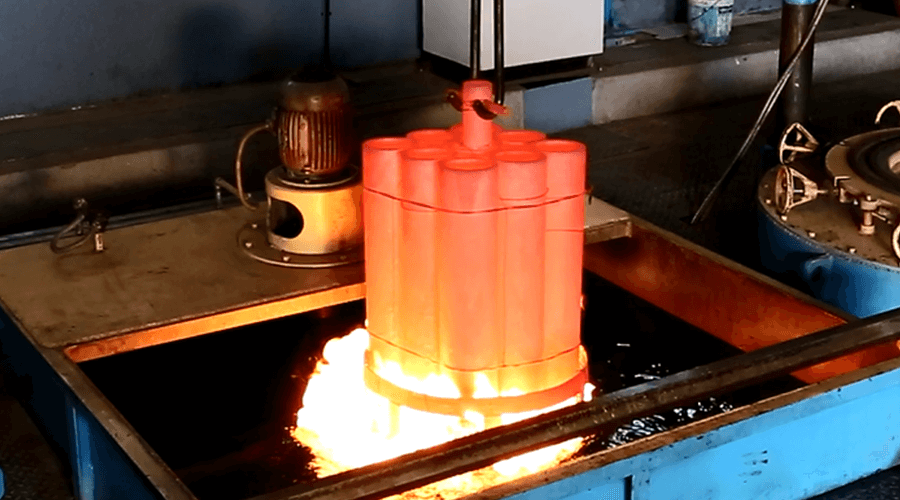

Quenching Oil Filtration

At Ram Engineering, we offer specialized quenching oil filtration services designed to optimize the performance and longevity of quenching oils used in heat treatment processes. Our comprehensive filtration solutions include

Tailored filtration systems designed to effectively remove contaminants such as particulates, oxides, and carbon residues from quenching oils.

Utilization of advanced filtration technologies to ensure thorough purification without compromising oil quality or heat treatment results.

Scheduled maintenance programs to monitor filtration performance and ensure consistent oil purity and efficiency.

Expert consultation to recommend the most suitable filtration solutions based on specific heat treatment requirements and operational conditions.

Compliance with industry standards to meet quality and performance specifications, ensuring reliable heat treatment processes.