A top automobile manufacturer in South India is facing a constant problem with the hydraulic oil and lubrication management system. They have 3 main distinct divisions; each division has approximately 100 power packs and numerous lubricated systems.

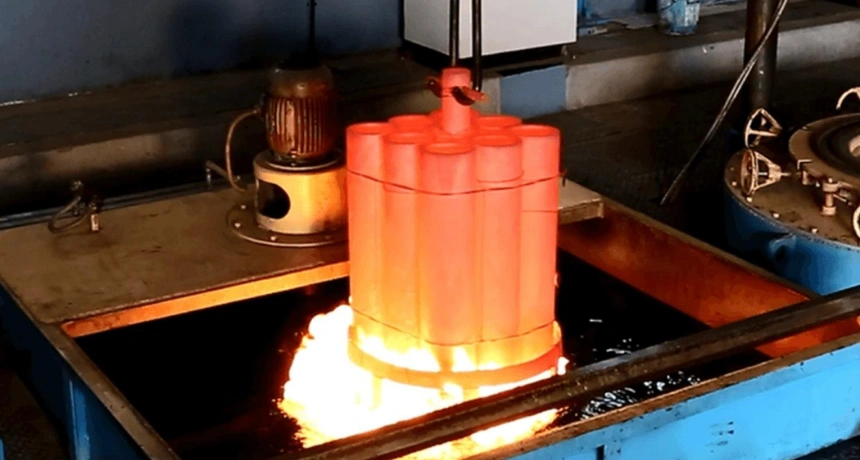

Crisis Averted – Quenching Oil Recovery in Record Time

Quenching oil is not simply a fluid in the high-stakes world of heat treatment; it is an essential technical medium that determines the metallurgical characteristics, dimensional stability, and general quality of your final products. Inconsistent hardness, more distortion,

Critical Hydraulic Power Pack Recovery Post-Heat Exchanger Burst

A heat exchanger within a primary hydraulic power pack (6000 Ltrs capacity) at a significant manufacturing plant in Coimbatore, Tamil Nadu, ruptured, causing a serious failure. A highly emulsified, non-functional fluid was produced as a result of this disastrous incident,

Life Extended & Downtime Averted in Cement Plant

Lube oil is essential to rotating machinery in all South Indian industrial operations, including cement factories, textile mills, power plants, and marine vessels. Equipment longevity, energy efficiency, and operational dependability are all directly influenced by its purity.

Tool Life Doubled & Odor Eliminated at a Precision Engineering Unit

Cutting oil problems affected a precision engineering facility in Bangalore, Karnataka, that specialised in automobile components. Despite regular top-ups, the fluid was rapidly becoming rancid, releasing unpleasant, disagreeable smells, irritating workers' skin,

Eliminating Rejects & Boosting Profitability at a Hose Manufacturing Company

A well-known hose manufacturer in Chennai, Tamil Nadu, that specialised in automotive and industrial hoses with metal fittings, had a persistent and expensive quality problem. Tiny metal fines and dust particles were contaminating their Rust Preventive Oil (RPO) dipping baths,

Unlocking Hidden Energy Savings at a Bangalore Textile Company

In Bangalore, Karnataka, a sizable textile industry used a furnace oil tank with a capacity of 12,000 litres to power its dyeing and processing activities. However, the furnace oil had become extensively polluted with carbonised particles, ash,

Recovering Valuable Base Oil & Halting Massive Losses for a Chennai Manufacturer

An ongoing and expensive issue with their base oil inventories plagued a major oil manufacturing facility in Chennai, Tamil Nadu. Base oils, purchased and sent from the seaport, were often arriving heavily contaminated. They had a lot of water, dust, and carbon particles

Rapid Diesel Recovery & Generator Restoration Post-Heavy Flood

A crucial industrial facility's 20,000-litre (20 KL) generator fuel tank became seriously contaminated during a period of severe floods in Chennai, Tamil Nadu. Floodwaters entered the tank, bringing a large quantity of debris, silt, and microbiological pollutants while also thoroughly mixing with the High-Speed Diesel (HSD).

Restoring Heat Transfer & Cutting Fuel Costs at a Chemical Plant

A sizable thermic fluid heater system was crucial to the maintenance of exact temperatures for its vital reactor activities at a significant chemical production facility in Bengaluru, Karnataka. After operating continuously for a number of years, the thermic fluid had deteriorated significantly,

Restoring a Critical Power Transformer Post-Flood Contamination

After an extraordinary flood, a crucial 50 MVA power transformer at a large industrial power substation in Chennai, Tamil Nadu, had its transformer oil seriously contaminated. Floodwaters had gotten into the transformer's conservator tank,

Drastic Reduction in D60 Procurement for a Fuel Dispenser Manufacturer

One of the leading manufacturers of petrol pump dispensers in Coimbatore, Tamil Nadu, used D60, a specialised hydrocarbon solvent with characteristics like fuel but a higher flash point, as a crucial medium for evaluating the leaks in their dispenser parts.

Rust Eradication & Gearbox Revival at a Karnataka Sugar Mill

The main gearbox of a well-known sugar mill in Karnataka, which is essential to ongoing production, experienced a serious problem. Significant moisture infiltration had happened as a result of a failing breather,

Varnish Elimination & Uninterrupted Power Generation at a Major Thermal Power Plant

A crucial 500 MW steam turbine of a sizable thermal power plant in Visakhapatnam, Andhra Pradesh, was having persistent problems with its turbine oil. The primary bearing surfaces and the servo valves of the Electro-Hydraulic Control (EHC) system were developing varnish deposits in spite of routine particle filtering.

Achieving NAS 4 Purity & Seamless Commissioning for a Critical Industrial System

A significant new hydraulic power transmission system with intricate, lengthy pipework was being put into service for a big industrial client in Chennai, Tamil Nadu. The system posed a serious cleaning difficulty since it included both freshly constructed pipes and pre-existing components.

Rapid Diesel Tank Restoration & Safety Excellence Post-Contamination

A 20,000-litre (20 KL) diesel storage tank at a vital industrial site in Coimbatore, Tamil Nadu, presented a significant difficulty. The tank had developed substantial coatings of rust, dust, and carbon particles as a result of internal problems and extended use,

Gear Misalignment Detected Early, Catastrophe Averted for a Major Manufacturer

Proactive maintenance, including a regular 3-month oil analysis program for its vital manufacturing gear, was a point of pride for a prominent industrial firm in Coimbatore, Tamil Nadu.

Averting Major Electrical Fire & Production Halt at a Manufacturing Plant

A significant, invisible danger existed in the main electrical distribution panel of a big, 24/7 industrial facility in Bangalore, Karnataka. A hazardous thermal anomaly resulted from the internal components' significant overheating problems,

Detecting Overheating Bearing & Preventing Catastrophic Conveyor Failure at a Cement Plant

A vital conveyor belt system that carried raw materials to the kiln was a major component of a sizable cement production facility in Andhra Pradesh. Due to early-stage wear and insufficient lubrication,

Transforming Maintenance & Boosting Uptime at a Major Automobile Manufacturer

With several manufacturing lines and hundreds of vital rotating assets (such as fans, gearboxes, motors, and pumps), a major car manufacturer in Chennai, Tamil Nadu, had to optimise its maintenance plan. Even though they conducted periodic vibration analysis,

Individual Vibration Analysis in a High-Speed Manufacturing Plant System

A prominent automotive component manufacturer in Hosur, Tamil Nadu, operated a large-scale plant with multiple CNC machines, blowers, pumps, gearboxes, and precision drive systems running in 3 shifts. Despite conducting scheduled maintenance and occasional vibration checks, the facility suffered recurring unplanned shutdowns, particularly with high-speed spindles and exhaust blowers.

Achieving NAS 4 Purity & Seamless Commissioning for a Critical Industrial System

A crucial new hydraulic power transmission system with substantial, intricate pipes was being put into service for a significant industrial client in Chennai, Tamil Nadu. The system posed a serious cleaning difficulty since it included both freshly constructed pipes and pre-existing components.

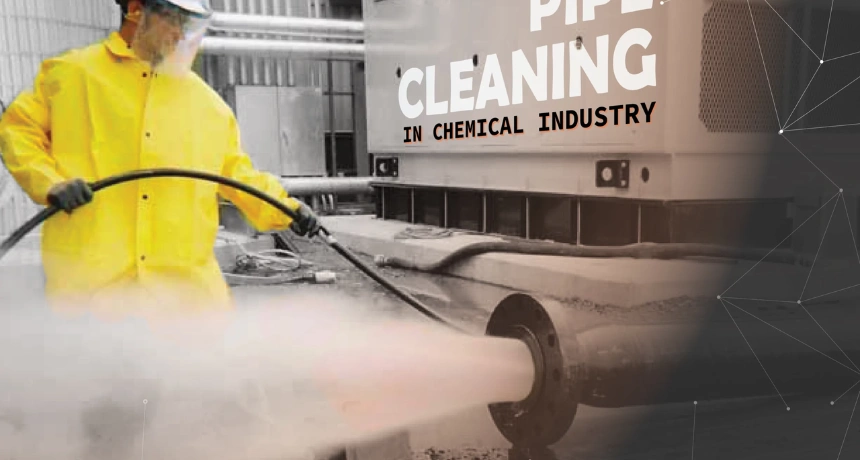

Restoring Purity & Compliance for Critical Process Lines at a Pharmaceutical Plant

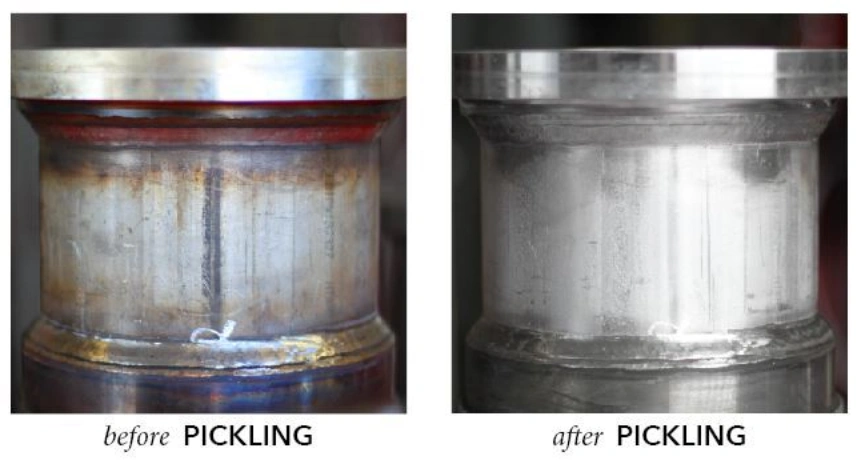

A major problem with its stainless steel (SS 316L) process pipes, which are used to convey highly purified water (WFI, or water for injection) and active pharmaceutical ingredients (APIs), was encountered by a major pharmaceutical production facility in Hyderabad, Telangana.

Restoring Purity & Compliance for Critical Process Lines at a Pharmaceutical Plant

A major problem with its stainless steel (SS 316L) process pipes, which are used to convey highly purified water (WFI, or water for injection) and active pharmaceutical ingredients (APIs), was encountered by a major pharmaceutical production facility in Hyderabad, Telangana.

Restoring Efficiency & Preventing Shutdowns at a Textile Processing Plant

The efficiency of the hot water and steam condensate return pipes of a sizable textile manufacturing facility in Tirupur, Tamil Nadu, significantly declined. These crucial lines had collected significant calcium carbonate scale and other mineral deposits over time,

Plate Heat Exchanger Maintenance for Food Processing Units

A leading food processing manufacturer in South India faced recurring challenges with over 60 PHE units across various production lines. Despite routine internal maintenance, they experienced.

Supply of PHE Spares & Gaskets for Process Manufacturing

A leading process manufacturing company in South India was facing recurring issues with their Plate Heat Exchangers used across cooling, heating, and heat recovery applications. The facility operated multiple PHE units across three major production divisions, each division running several heat exchangers under varying temperatures and pressure conditions.

Heat Exchanger Servicing & Retrofits for Chemical Plants

A leading chemical manufacturing facility in South India faced persistent performance issues with its heat exchangers used in critical heating and cooling operations. The plant operated multiple shell & tube and plate heat exchangers that had been in service for over ten years.

Thermal System Optimisation for Engineering Manufacturing

A leading engineering manufacturing facility in South India faced persistent challenges with temperature instability across its production processes. Multiple heating and cooling systems operated independently, resulting in energy losses, uneven temperature distribution, and frequent system adjustments.

Cooling Tower & Closed-Loop System Optimisation for Power Plants

A large power generation facility in South India faced recurring challenges with corrosion, scaling, and reduced cooling efficiency across its cooling towers and closed-loop systems. These issues led to rising energy consumption, frequent equipment maintenance, and inconsistent plant performance.

Get expert advice for all your oil and pipeline needs

Every solution begins with a conversation.

ASK AN EXPERT